MIND (Mixed-Integer Nonlinear programming for membrane systems Design) is an optimization software to automatically determine the most cost-effective design for a gas filtration process based on polymeric membranes.

Membrane gas separation by means of synthetic polymeric membranes is a well-established technology for several industrial applications such as the production of nitrogen from the air, hydrogen recovery from ammonia plants and refineries, and natural and biogas treatment to reduce CO2 emissions.

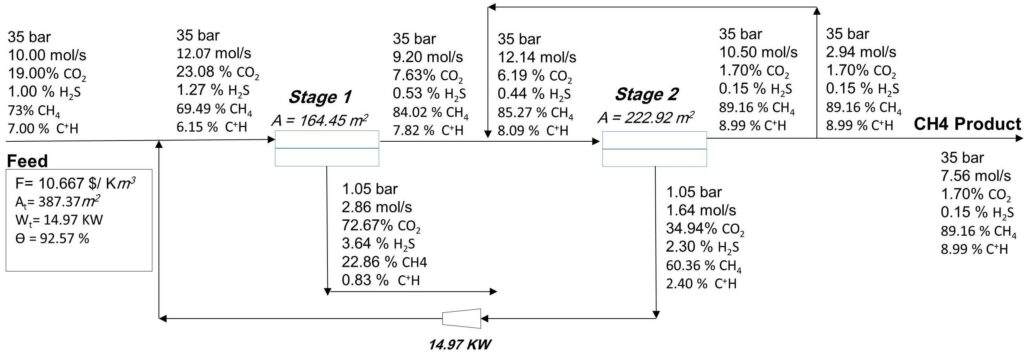

Membranes act as a selective filter: when a mixture enters the membrane (for example a mix of methane and other gases), it is separated into two flows: the product, enriched in the desired component, and the “waste” (or secondary product). For obtaining cost-effective processes with the desired output, it is often necessary to design multi-stage systems (see Fig. 1). The design (system configuration, membrane size) and the operational conditions of each stage (applied pressures) impact both the quality of the product and the cost of the solution.

Traditionally, process design is the result of human expertise combined with a trial-and-error simulation process to assess the impact of different designs and operational conditions. This process is tedious and time-consuming often leading to solutions far from the optimal one, due to the evaluation of a limited number of process configurations.

The optimization approach for process design aims to explore automatically (and implicitly) the full set of meaningful configurations in order to ensure that the process operates under the most favorable conditions. Our optimization strategy combines a standard local search procedure (namely the Knitro solver) with an ad-hoc global optimization procedure (see Chapter 3 of B. Addis HDR Manuscript for some details of the optimization methods behind it).

MIND allows optimizing a generic gas separation membrane process under the user’s choices: the input mixture (composition, pressure, flowrate) the employed membrane types (costs and filtration performances), and the working ranges for the devices (pressures, membranes’ area).

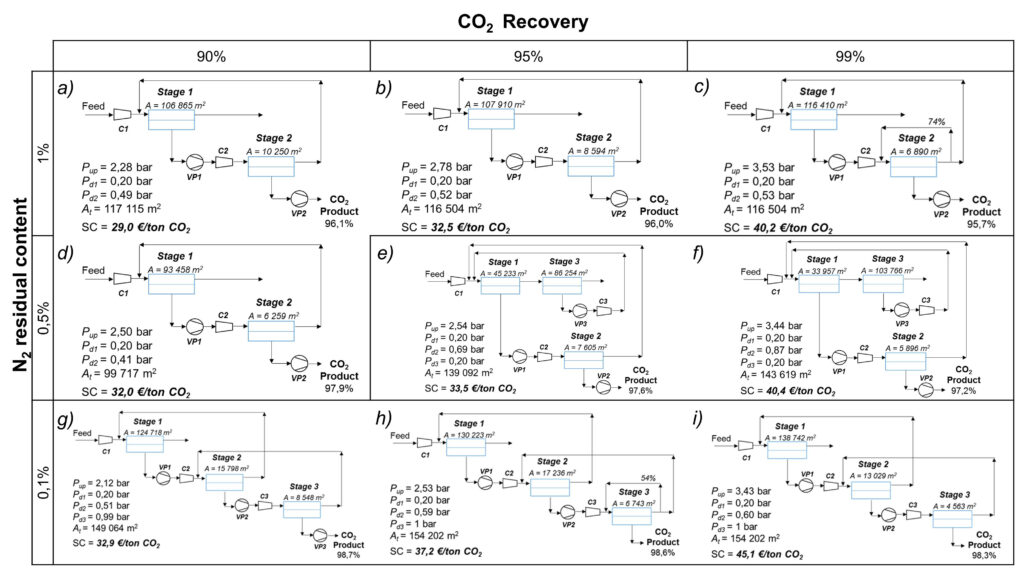

In Fig 2, an example of a full case study performed with MIND is presented (CO2 recovery from blast furnace). The best configuration for different performance indicators (CO2 recovery, N2 residual content) is presented. Two points are worth mentioning: first, MIND proposed some configurations (self-loops) that were not considered in the current state of the art; second, the proposed solutions improved at least by 20% upon the results with respect to the simulation-based approach with a shorter work-time. To give a general idea, the overall analysis was performed over some weeks on a personal computer. The same analysis would need more than 3 months of an expert using the trial-and-error simulation-based approach.

MIND software is the result of a collaboration of a multi-disciplinary team. The permanent members of the team are Bernardetta Addis (LORIA), Christophe Castel and Eric Favre (LRGP) and Veronica Piccialli (University of Rome). Its maturation was partially funded by the SATT Grand-Est.

The MIND core algorithm is registered under an APP license on 13/08/2018: IDDN.FR.001.460015.000.S.A.2018.000.31500

Projects/Publications where MIND has been used or is currently in use:

- MEMSIC tech (exclusive industrial license).

- PGMO 2018 – IMPRESS the Impact of optiMization in PRocESs Synthesis. Interdisciplinary project in collaboration with LRGP laboratory and EDF

- T. Neveux, B. Addis, C. Castel, V. Piccialli, and E. Favre. A comparison of process synthesis approaches for multistage separation processes by gas permeation. In Proc. of ESCAPE32 – 2022

- M. Bozorg, Álvaro A. Ramírez-Santos, B. Addis, V. Piccialli, C. Castel, and E. Favre. Optimal process design of biogas upgrading membrane systems: Polymeric vs high performance inorganic membrane materials. Chemical Engineering Science, 225:115769, 2020.

- M. Bozorg, B. Addis, V. Piccialli, Á. A. Ramírez Santos, C. Castel, I. Pinnau, and E. Favre. Polymeric membrane materials for nitrogen production from air: A process synthesis study. Chemical Engineering Science, 207:1196 – 1213, 2019.

- Á. A. Ramírez Santos, M. Bozorg, B. Addis, V. Piccialli, C. Castel, and E. Favre. Optimization of multistage membrane gas separation processes. Example of application to CO2 capture from blast furnace gas. Journal of Membrane Science, 566:346–366, 2018.

- A. Macali. Membrane Separation Processes Using Machine Learning Based Mathematical Programming Models. Ph.D. thesis, 2023.